|

|

|

|

TAKE THE TOUR

We have had Dorsets since 1985. Our Dorset flock was created from buying out two different breeders. They were closed flocks that were selected for important production traits. Only two outside rams were used prior to the closing of our flock. Ewes = 320.

Hunter Dorsets –

A 320 ewe flock of easy care registered Polled Dorsets, run as a commercial flock. A low labor, efficient, practical operation done as a part-time job. |

|

This is a 100% Closed Flock. Free of OPP, Footrot, Q fever, Caseous, B. Ovis, etc… We have no negative recessive genes, so we linebred for predictability and uniformity of the flock. I regularly mate half-siblings and I keep several rams, usually 8 to 10 just for my own use.

Our flock is known for its success in a wide variety of climates and management conditions. Purebred and commercial breeders seek us out because of our practical true dorset type of sheep that perform. I believe the sheep should work for you - thus my advertising slogan; 'Real Dorsets Work for You'.

| Selection for maternal traits, and commercially important traits: |

|

Accelerated lambing |

Gain, thickness, carcass quality |

|

Pasture use |

Longevity and low death loss |

|

Durability, heat tolerance |

Maternal traits, milk production |

|

Lambing % |

Ease of care |

Photograph Above — 5 Year old Daughter Allison with ewe 83200; our dog Jodi 11 years old in the backgorund during fall 2005 lambing.

Flock: Production Cycle and Management

General Information — Yes, we are a pasture/forage based operation. Some might misinterpret this statement to mean that we never feed any grain – only pasture. We do feed grain to the ewe flock at the critical stages of late gestation and lactation. (If we have any lactation groups on pasture in the spring they do not get grain.) Our climate does not allow for year-around grass production. Also we are lambing at multiple times and out of season so a 100% limitation of grain is not possible. However when we have pasture available that is all our ewes need to thrive; unlike some pampered flocks which need grain and shelter on a year around basis just to survive.

Winter Flock Management

— Ewes which are not in the barn lambing or getting ready to lamb are wintered outside without shelter. They are self fed first cutting big round bales of hay. If production cycle indicates or temperatures are very cold they might also be fed some grain. |

|

|

Summer Flock Management

— During the summer the entire ewe flock is kept outside (no shelter) on pasture. We rotationally graze our pastures and we do not feed grain to the ewe flock during our pasture season. |

Three lambing groups — Accelerated Schedule lambing at 7-8 month intervals.

September / October December / January March/April / May

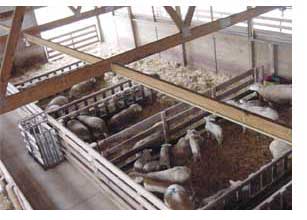

Gestation — Ewes Gestate outside without shelter until about 2-4 weeks prelambing. Then the ewes come to barn; they are fed a gestation ration at about 1.5 #, plus first cutting grass hay in small bales. Group size is 40 to 50 ewes per pen.

Lactation — Ewes Lactate in the barns for about 60 days. (The April/May lambing group usually has some part of their lactation on pasture without grain.) I feed legume or grass/legume hay small bales, plus grain 2 lbs. Ewes are in lambing pens about 2-3 days. Afterwards ewes and lambs go to a 'mixing pen' of 10 to 15 ewes for a few days, then move on to larger pen of lactating ewes. Group size is 30 to 40 ewes per pen.

|

| Lambs — With our Fall, Winter, and Early Spring lambing groups no grass is available. So those lambs are inside with the ewes and have access to creep feed. With high priced land ($3000.00 +/acre) and lower cost grain in our area it makes more sense to feed our lambs; especially since they are already started on feed. We have lambed on pasture before and lactate some groups on pasture for our late spring lambing- those lambs would not be creep fed. Management is geared to the most practical and profitable method for a lambing group. After weaning all lambs are all self fed a 16% grain ration (unless a pasture group) to market weight. The ewe lambs are moved to hand feeding plus a pasture program as quick as possible. |

Replacement Ewe Lambs — Kept separate from ewe flock and fed the first year of their lives. We lamb winter and spring born ewe lambs at 12 months of age. Fall born ewe lambs lamb at 15 months of age in the winter group. Our replacement ewe lambs are moved to a hand feeding program by about 120 days of age. These replacements depend heavily upon pasture/forage as their base. However to get maximum development early for early breeding we hand feed them about 2 lbs grain in addition to their forage.

Vaccination and Health Program — Healthy sheep = less cost, less labor.

| Ewe flock pre-lambing vaccines = CD/T + Pasturella |

| Lambs = TAT at tail docking. 2 CD/T + Pasturella |

| Ewe Flock - Abortion vaccines after weaning. |

| Deworming: Ewe Flock ivomec/tramisol annual rotation. Panacur for tapeworms if needed only. Worming at proper times. Lambs dewormed 2 - 3 times. |

Pasture Use

We use pasture as long and as much as we can. We also flush with lush pasture for the winter lambing group. We Use intensive grazing, a section of 15 acres of pasture at home is broke into 13 paddocks. Rotation depends upon season and plant growth - usually 3 to 4 days.

Pastures are fertilized and I renovate some paddocks each year. Sub-division fencing is 4 wire 14 ga hi-tensile for 1.25 to 1.33 acre paddocks with electric cable gates. Perimeter fences are either 12 ga. 8-10 strand hi-tensile wire or woven wire. |

|

| Water is available in every paddock with above ground water system. Sheep are restricted to a sacrifice area or barns in the winter to avoid damaging pastures and reducing their carrying capacity the following spring. |

Facilities, Equipment, Land

General Information

— At the time of this writing (spring of 2004) we have excellent facilities. When I moved to this location in the fall of 1984 there were no buildings, utilities, driveways, or fences. So current state of efficient facilities are the result of progress over time. |

|

|

Facilities at Home — I waited a long time to be able to build the new barn. Many purbred breeders have outside money paying for their excessively large and/or extravagant facilities that the sheep can never pay for. All of our sheep & farm equipment and buildings are paid for and paid for by the sheep income. Our facilities our nice, & newer but practical. I try to build most of our feeders and other equipment. |

The New portion of the Main Sheep Barn built in the winter of 1999 is 52 x 70 x 11. The 40 x 70 section is curtain sided; the 12 x 70 ‘lean to’ section is open to the east.

|

The Original barn was 24 x 40 x 8 built in 1984. In 1989 the West Barn 40 x 48 x 10 was built for machinery, hay, and sheep. I used the north bay of this barn (16X40) for lactating ewes during winter and spring lambings. In 1999 the new barn was added to the original 24 x 40 barn. The 1999 sheep barn is 52 x 70 x 11. It was not intended for any hay or straw storage. We may build another barn will be just to the west of it for either machinery or hay so that we can use the 52 x 70 just for the sheep.

| 24x24 Straw Shed built fall 2005 |

|

Rental farm - since 1988: Pasture + barns + storage — Currently 7 acres pasture plus the use of three barns for sheep, for hay (400 bales), straw (550 bales) and storage of our hay making machinery. A 24 x 72 barn has three concrete lots. A 30 x 60 barn, half used for sheep, half hay storage. Use of a third building to store farm equipment in. Lambs are finished in the 24 x 70 building and we winter stud rams there. Replacement ewe lambs are grazed and grown out here - then moved home just prior to lambing. We also graze the early spring pasture with weaned ewes.

|

|

| Below is our 30x78 Farm Shop and Hay Storage Building. |

|

I own the farm equipment needed for a livestock operation only. We only own the feed handling, manure handling, and hay making equipment.

Hay making equipment - wagons, baler, mower, rake. JD 4020 Tractor. Bobcat Loader

Artsway Grinder/Mixer. Tandem Axle manure Spreader, Trailers-Sheep & Flat-bed.

Land Use — Total land farmed for the 250-275 ewe flock operation is about 50 acres of pasture and hay. Pasture ground is about 23 acres:

| Home: 15 of the 17 acres is pasture in 13 paddocks. |

| Adjoining 3 acres: Was pasture, in the past we seeded to annuals in rotation (sudangrass & ceral rye). Currently it is seeded to alfalfa and harvested as hay. We do pasture it after each cutting for about 3 days. |

| Rental farm: Was more acres and crop residue. Now 7 acres un-improved pasture. |

| Adjoining 4 acres: Mixed hay production, acquired for 2002 season. |

Hay field on 325 N - rented 3 acres.

Hay field at Dad's (30 miles away); big round bales of hay produced here.

Rental or Shares on hay fields= Varies from year to year from 0 to 20 acres.

About 20 to 40 acres of wheat ground baled for straw each year. |

| Handling System — My best investment; it is used often. We rarely catch sheep, we run them thru the handling system for sorting, deworming, vaccinating, etc.. The lots for the orginal 24 x 40 barn, double as holding pens for the handling system. Our system is permeate wood/ posts, with mechanical stop and sort gate which are galvanized. |

|

Flock Feeding Program

Sheep Mineral, fed free choice year around to the flock.

|

Hay use: About 800 lbs of hay fed per ewe and her offspring. (Annual 80 tons) We bale as much as we can ourselves. Then purchase hay during the growing season, by the ton, in large quantities (entire fields, semi-loads, etc.). We use big round bales for outside feeding to reduce labor and save money. Many of our round bales are harvested from the excessive spring growth on our own pastures. Inside the barns we use small bales of hay - I try to limit feed the better quality have to keep cost per ewe per day in line. |

Straw & Bedding — We use 600 to 700 heavy bales of straw annually. Coarse aglime (called stone sand) is used in the lots, and barn as a floor. Some regular replacement is needed after barn cleaning.

Grain rations and feed making for the sheep operation.

I use a 2.5 ton Artsway grinder/mixer to make all bulk rations for the farm. The farm buys premix and supplements from my feed company ‘Hunter Nutrition’ The premixes are used with soybean meal and coarsely ground corn to make several very cost effective rations. Pelleted supplement is blended with our corn to make ewe rations.

I buy ingredients in bulk = 10 tons corn, 3 ton soybean meal - the two west bins hold these. Also we have three feed bins, plus feed boxes for made up feed.The mixer delivers the feed to the bulk bins going into the sheep barn and into the self-feeders.

We can mix 2.5 ton is 45 minutes or 4 batches (10 tons) in three hours and move the feed where it needs to go. Cost per ton for the mixer and ingredient storage bins is just a few dollars per ton and all the rations have the highest fortification.

Sales

We sell Breeding Rams & Ewes, Slaughter Lambs, and Sheep for Research.

Our breeding stock is sold to purebred and commercial producers who are interested in production. All of our Dorsets are registered; call for prices on breeding rams and ewes. We usually sell about 50 head of breeding rams a year and all the good ewe lambs we have available. Most of our market lambs go to grocery stores in Lafayette. I have standing weekly orders for those lambs so year around production is required. These market lambs are usually intact males (leaner, to an older age); the stores want large carcasses (average 82 #) which greatly increases our profit. We also sell some market lambs direct for the ethnic trade. Research sheep sales are driven by our consistent high quality and disease free status, especially being Q Fever free.

Labor Required - Flock ran as an efficient part-time profitable business.

I do most of the work with help from my son Kyle who just turned 14. We do morning and evening chores together (before and after Hunter Nutrition opens); time varies depending upon lambing, but it is not a large amount. I do the major farm/sheep work on weekends; such as barn cleaning, etc.. Very little hired labor is used - usually some hay help at baling. At peak times I may have some extra help with tail docking, feed grinding, or baling. Our very low labor is a sharp contrast to other flocks about our size.

For example I know of a few 125 ewe flocks which have the equivalent of 2 full-time people. Another example is a 300-400 ewe flock which uses full time, seasonal, and part time help which adds up to equal 4 full time employees. This flock is running 1 fulltime man per 60 to 100 ewes. This is too high regardless of whether it’s a commercial or purebred flock. I added up my labor, and the hired labor I use and we are equal to about 1/2 full time man on a flock of 200 ewes.

Production Levels -

Lambing Percent: Including ewe lambs, very old ewes, etc. is about 196%.

Death loss to 12 months of age is about 12%. (This is all lambs born and calculated after going through not only the lambing barn, but clear till the lamb crop is 12 months old or has been sold.)

The Future

|

I see lots of potential for our flock and others in the US.

A few things I believe are needed for a sheep operation to be successful:

|

Easy Care Sheep

|

Lambing % about 2.0

|

|

Low labor at lambing,

feeding, and handling

|

Very low death loss

|

|

Freedom from disease

(saves $ and labor)

|

Input cost control done

in the right areas

|

|

Market your own products!

|

|

|

|

|